Analytical Applications of Ultrasound

Free download. Book file PDF easily for everyone and every device. You can download and read online Analytical Applications of Ultrasound file PDF Book only if you are registered here. And also you can download or read online all Book PDF file that related with Analytical Applications of Ultrasound book. Happy reading Analytical Applications of Ultrasound Bookeveryone. Download file Free Book PDF Analytical Applications of Ultrasound at Complete PDF Library. This Book have some digital formats such us :paperbook, ebook, kindle, epub, fb2 and another formats. Here is The CompletePDF Book Library. It's free to register here to get Book file PDF Analytical Applications of Ultrasound Pocket Guide.

Contents:

Applications of UltrasoundBased Detection Techniques. List of Abbreviations. Luque material measurements mechanical membrane metals methods monitoring nebulization obtained operating organic oxidation particles permission of Elsevier piezoelectric pressure pulse R. Compton reaction reagent Reproduced with permission resonance sample preparation scattering signal slurry solid samples solution solvent sonication Sonochem Sonochemistry specific spectrometry spectroscopy standing wave step surface surfactant target analytes temperature tion transducer ultrasonic bath ultrasonic velocity ultrasonic wave ultrasound ultrasound-assisted US-assisted USAL variables viscosity volume wavelength.

For sound waves, since the distance For sonochemical applications, however, there is a minimum time period pulse which must be exceeded if any cavitational effects are to be observed.

This is This has been termed "false sonochemistry" although many industrialists would argue that the term false may not be correct because if the result of ultrasonic irradiation assists a reaction it should still be considered to be assisted by sonication and thus "sonochemical". Home Subjects Chemistry Analytical Chemistry. Ultrasound in Chemistry: Analytical Applications.

Selected type: Hardcover.

Added to Your Shopping Cart. Out of stock. View on Wiley Online Library. Conventional methods of bacterial inactivation involve thermal treatments, such as pasteurization.

These treatments generally result in undesirable flavors and the loss of nutrients. Ultrasonic treatment has been used to inactivate bacterial populations [ 73 ]. This is due to cavitation effects: pressure changes produced by the ultrasonic waves cause microbiological inactivation [ 3 , 73 ]. The microbiological damage resulting from the application of various ultrasound wave amplitudes depends on factors such as contact time with the microorganism, microorganism type, food quantity, composition, and treatment temperature [ 74 ].

Microbial resistance varies among microorganisms, i. Studies have shown that larger or longer cells are more susceptible to ultrasound because they have more a larger contact surface and are therefore more exposed to the pressure produced by cavitation [ 75 ]. Gram-positive bacteria are less susceptible to ultrasound compared to Gram-negative bacteria, although results have shown that rod-shaped bacillus microorganisms tend to be more susceptible than cocci [ 76 ]. Gram-positive bacteria are likely less susceptible to ultrasound because of their thicker cell walls, which contain an adhesive peptidoglycan layer [ 77 , 78 ].

In general, microorganisms that produce spores exhibit a greater resistance to heat and ultrasound [ 74 , 75 ]. A considerable amount of data on the impact of ultrasound on microbial inactivation is available. For this reason, a new method for antimicrobial treatment could feature the combined effects of pressure and ultrasound manosonication , ultrasound and heat thermosonication , or ultrasound, heat, and pressure manothermosonication [ 79 ]. These are likely the best microbial inactivation methods because they are more energy-efficient and effective in inhibiting microorganisms than conventional methods.

The effectiveness of ultrasonic treatments requires prolonged exposure to high temperatures, which may deteriorate functional properties, sensory characteristics, and the nutritional content of foods [ 73 ]. In combination with heat, ultrasound can accelerate the rate of food sterilization, thereby decreasing the necessary duration and intensity of heat treatment and the resulting damage.

- Analytical Applications of Ultrasound, Volume 26;

- Best Practices: Managing People: Secrets to Leading for New Managers (Collins Best Practices Series)!

- Ultrasound in Chemistry: Analytical Applications;

- Ultrasound Application to Improve Meat Quality;

The inactivation of Salmonella typhimurium, Salmonella derby, Salmonella infantis, Yersinia enterocolitica, and a pathogenic strain of Escherichia coli was studied in inoculated samples treated for 0. The total viable bacterial counts decreased by 1. The reduction of the population in the skin was significantly greater than that in the meat, although no significant differences were observed between the types of bacteria. However, the study by Smith et al.

Communication Error Occurred.

They reported no effect after ultrasound on Salmonella or on E. Some authors [ 82 ] have studied the elimination of Gram-negative bacteria Salmonella anatum, Escherichia coli, Proteus sp. Other reports show that treating chicken carcasses in the process line with steam and ultrasonic treatments significantly reduces the population of Campylobacter in contaminated poultry.

- The real Anita Hill: the untold story!

- 7 Reasons to Believe in the Afterlife: A Doctor Reviews the Case for Consciousness after Death!

- Account Options?

- Management of Patients with Neuromuscular Disease!

- The European Health Report 2002 (WHO Regional Publications, European)!

The total viable content decreased by approximately three logarithmic units when steam and ultrasound were applied immediately after slaughter [ 83 ]. Ultrasound treatments combined with lactic acid may be a suitable method for decontaminating poultry carcass skins. Ultrasound effects depend on frequency, amplitude, time, and temperature [ 84 ] as it was demonstrated on the inactivation of suspensions containing Escherichia coli, Staphylococcus aureus, Salmonella sp.

These three parameters affected the inactivation of bacteria in pure cultures. The results showed increased microbial inactivation for longer treatment periods, particularly when they were combined with high temperature and amplitude. Meat treated for the longer period showed the largest reduction of microorganisms during storage [ 21 ].

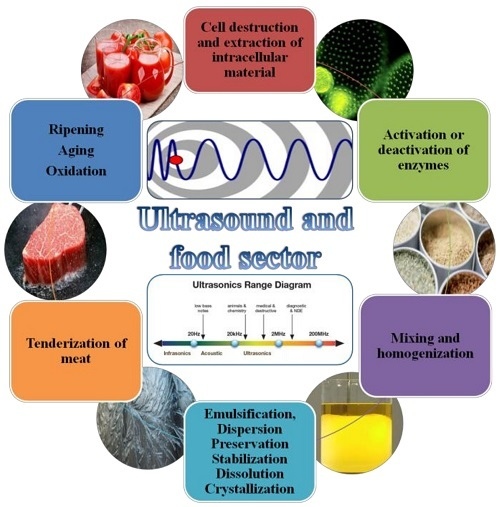

Selected and potential applications of ultrasound mainly in the field of food preservation and product modification were discussed. High-intensity ultrasound generates acoustic cavitation in a liquid medium, developing physical forces that are considered the main mechanism responsible for the observed changes in exposed materials.

These forces include acoustic streaming, cavitation, shear, micro-jet, and shockwaves. The quantity of energy released by the cavitation depends on many factors such as treatment medium and ultrasound frequency. Ultrasound has a wide range of applications in the food industry. It can be used as a processing aid in extraction, crystallization, freezing, emulsification, filtration, and drying. Applications of ultrasound in meat have been reported with interesting advantages in freezing, thawing, meat brining, and tenderizing.

Ultrasound has also been shown to improve physicochemical characteristics, preparation processes for meat products, microbiological content, and sensory characteristics in fresh and processed meat. Acoustic cavitation may induce the mechanical rupture of the myofibrillar protein structure with significant effect on collagen characteristics and meat textural properties.

High-intensity ultrasound reduces microbial loads in meat, resulting in the destruction of living cells and this effect remains during cold storage. Like most innovative food processing technologies, high-power ultrasonics needs to be developed and scaled up for each application. The authors declare that they have no interest or benefit arising from the direct applications of this chapter.

Licensee IntechOpen. This chapter is distributed under the terms of the Creative Commons Attribution 3. Help us write another book on this subject and reach those readers. Login to your personal dashboard for more detailed statistics on your publications. By Niamh Burke, Krzysztof A.

Analytical Applications of Ultrasound - F. Priego Capote, M.D. Luque de Castro - Google книги

Ryan and Catherine C. Edited by Dongpo Li. We are IntechOpen, the world's leading publisher of Open Access books. Built by scientists, for scientists. Our readership spans scientists, professors, researchers, librarians, and students, as well as business professionals. Downloaded: Abstract High-intensity ultrasound offers an alternative to traditional methods of food preservation and is regarded as a green, versatile, popular, and promising emerging technology.

Keywords ultrasound cavitation emerging technology minimal processing meat quality. Introduction Evolution of food processes is driven by changes in consumer preferences and the need to produce safe and high-quality foods. Power ultrasound Power or high-intensity ultrasound has emerged as a new and complementary technology with a high number of potential applications. Applications in food Ultrasound has potentially a wide range of applications in the food industry. Applications in meat The use of ultrasound in the meat industry, which began with the evaluation of live cattle fat and muscle, has been conducted since the s.

No effect on collagen. No effect on pH. Higher water holding capacity.

Increased free calcium. Changes in protein structure. Improved WHC at 4 d postmortem. Reduced hardness. Fragmentation of protein structures. Increase WHC. Increased pH. No interaction between ultrasound and aging. No changes in meat color and drip loss. Ultrasound reduced cook and total loss.

No change in cooking loss. Decreased the tendency to yellow. Decreased the muscle fiber diameter. No effect on heat-insoluble collagen.

Analytical Applications of Ultrasound

Weaken collagen stability. Ultrasound combined with actinidin decreased shear force more than actinidin alone. No change in oxidative stability at 4 d storage. Increases luminosity and reduces redness up to 8 d of storage. No effect on water holding capacity of meat.

SearchWorks Catalog

Decreased coliforms and psychrophilic bacterial load. Higher sensory tenderness. Reduces shear force. Produces more tender and juice meat. No effect on meat color. Higher mass transfer at higher ultrasound intensity. Diffusion coefficient increases with ultrasound intensity. Higher mass transfer and protein extraction.

Myosin denaturation at higher intensities.

- The Andromeda Galaxy

- Elephants and Savanna Woodland Ecosystems: A Study from Chobe National Park, Botswana

- The Winters Tale

- MicroRNAs in Development: Methods and Protocols

- Horseshoe Crabs and Velvet Worms: The Story of the Animals and Plants That Time Has Left Behind

- The Physical Foundation of Economics: An Analytical Thermodynamic Theory

- Engineering, Poverty, and the Earth (Synthesis Lectures on Engineers, Technology, and Society)