Styrenic Copolymers

Free download. Book file PDF easily for everyone and every device. You can download and read online Styrenic Copolymers file PDF Book only if you are registered here. And also you can download or read online all Book PDF file that related with Styrenic Copolymers book. Happy reading Styrenic Copolymers Bookeveryone. Download file Free Book PDF Styrenic Copolymers at Complete PDF Library. This Book have some digital formats such us :paperbook, ebook, kindle, epub, fb2 and another formats. Here is The CompletePDF Book Library. It's free to register here to get Book file PDF Styrenic Copolymers Pocket Guide.

Special purpose grades include high-temperature, clear and weather-resistant materials.

Styrenic Copolymer

Styrenic copolymers are increasingly being used in blends and alloys, and the properties of the styrenic polymers tend to predominate. The morphology, manufacture and properties of key materials are described here. Styrenic copolymers can be processed by all the common methods including injection moulding, extrusion and blow moulding. This review is extensively referenced in the text.

It is accompanied by summaries of the cited papers from the Rapra Polymer Library database formerly known as Rapra Abstracts. These papers are indexed to allow the reader to search for information on specific topics.

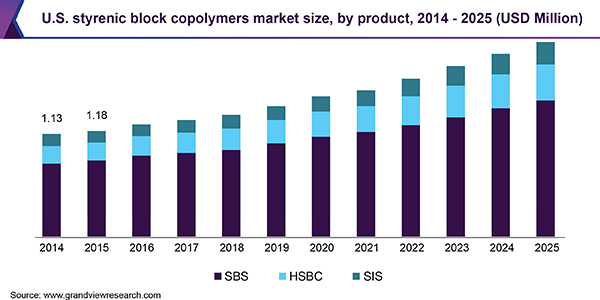

Also, involve distinct business approaches accepted by the decision makers. Market Forecast by Type The outlook for SBS in polymer modification is expected to be positive due to the stable growth of automotive production in developed regions, such as North America and Europe, coupled with the rising demand for home appliances in developing regions, such as Southeast Asia and Middle East. Download Tradeindia App Now. Increasing demand for SBS for polymers such as high impact polystyrene, ABS, EVOH, polyolefine and mass moulding compounds will contribute to future growth of the segment in terms of impact strength, durability and flexibility.

Special Purpose Grades. Abbreviations and Acronyms. More growth opportunities will turn up between and as compared to the past five years, suggesting rapid pace of change.

Elastomers

Companies quickly adapting to this changing landscape are emerging as the top performers and earning attractive revenues through sustainable transition, innovation, efficient pricing and sales execution strategies. Increases in both domestic and export-oriented revenues are observed for key players in the global Styrenic Copolymers market.

However, challenges such as increasing buyer bargaining power, emphasis on high-quality products at low costs are forcing significant changes in the Styrenic Copolymers supply chain. Table of Contents 2. Global Styrenic Copolymers Industry Overview 3. They are cheaper than other TPEs owing to their bulk consumption.

The outlook for SBS in polymer modification is expected to be positive due to the stable growth of automotive production in developed regions, such as North America and Europe, coupled with the rising demand for home appliances in developing regions, such as Southeast Asia and Middle East.

Search DSpace

However, the product demand in developed countries of North America and Western Europe is about to reach its saturation. Thus, these regions are expected to witness a relatively sluggish growth rate over the forecast period.

Several federal bodies do, however, regulate the applications in numerous end-use industries to ensure consumer health and safety. These regulations encourage the utilization of these and other thermoplastic materials for commercial applications to provide guidelines for prudent product usage. These copolymers display significant advantages for adhesives formulation since they easily flow at processing temperatures and act like reinforced elastic rubbers under standard application conditions.

Due to these properties, it also finds applications in other industries, such as vulcanized compounding and bitumen modification. Numerous agencies across the globe are continuously striving to increase the service life of pavements.

Additionally, the introduction of radial truck tires with PSI of pressure have increased the burden on existing pavements and highway infrastructures. The global footwear industry is a major consumer.

SBS is an excellent material in footwear manufacturing for several reasons that also make it ideal for roofing. In shoe soles, SBS contributes to a strong yet flexible product that can be waterproofed.

- Navigation Bar.

- More news from this section.

- The Thief Taker.

These benefits, along with the low cost and biocompatibility of these materials is driving their use in footwear applications. This allows the use of more stable hydrogenated formulating ingredients, providing systems of overall high stability, transparency, and clarity.

Productspecificaties

Increasing geriatric population and the subsequent rise in the number of healthcare facilities has driven the demand for medical equipment, devices, and materials with high waterproofing capabilities to reduce the risk of contamination and epidemics. These factors have led to the increased use of HSBC in medical devices to impart desirable properties, such as long-lasting durability and pathogen-resistance. HSBC formulations are much more stable than SIS formulations because the mid-block is fully saturated and thus provides excellent resistance against thermal degradation.

- Can Poetry Save the Earth?: A Field Guide to Nature Poems

- Slaughterhouse 90210

- The Ignorant Schoolmaster: Five Lessons in Intellectual Emancipation

- Knitting Bones (Needlecraft Mysteries, Book 11)

- OSPF Network Design Solutions (2nd Edition)

- Introduction to Large Truncated Toeplitz Matrices (Universitext)

- Secrets of Swiss Banking: An Owners Manual to Quietly Building a Fortune